Why lean management ?

This is the only program that

- Applies to organizations of all sizes, in industry or services

- Is fully aligned with the organization strategy

- Engages all employees transversally and develop their competencies

- Delivers sustainable improvements in global performance

- Is fully aligned with the organization strategy

- Engages all employees transversally and develop their competencies

- Delivers sustainable improvements in global performance

Why practical lean ?

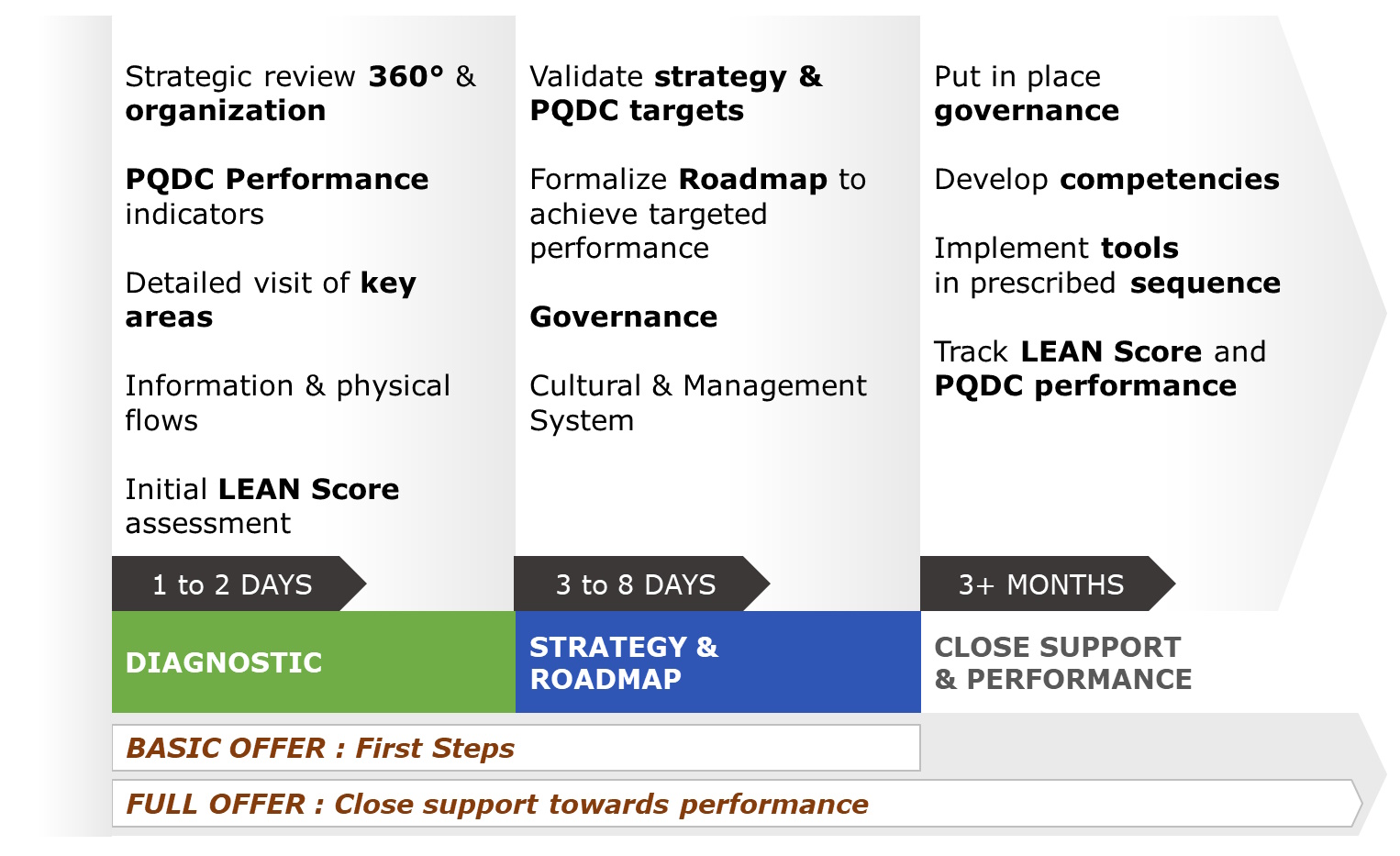

A successfull LEAN deployment requires

- A structured and progressive approach adapted to each organization

- An international experience of successful LEAN transformations

- Proficient technical skills inherited from historic LEAN designers

- Empathic coaching by managers who went several times through all these changes, to drive full engagement from all parties and deliver sustainable behavior changes

- An international experience of successful LEAN transformations

- Proficient technical skills inherited from historic LEAN designers

- Empathic coaching by managers who went several times through all these changes, to drive full engagement from all parties and deliver sustainable behavior changes

OUR FINDINGS

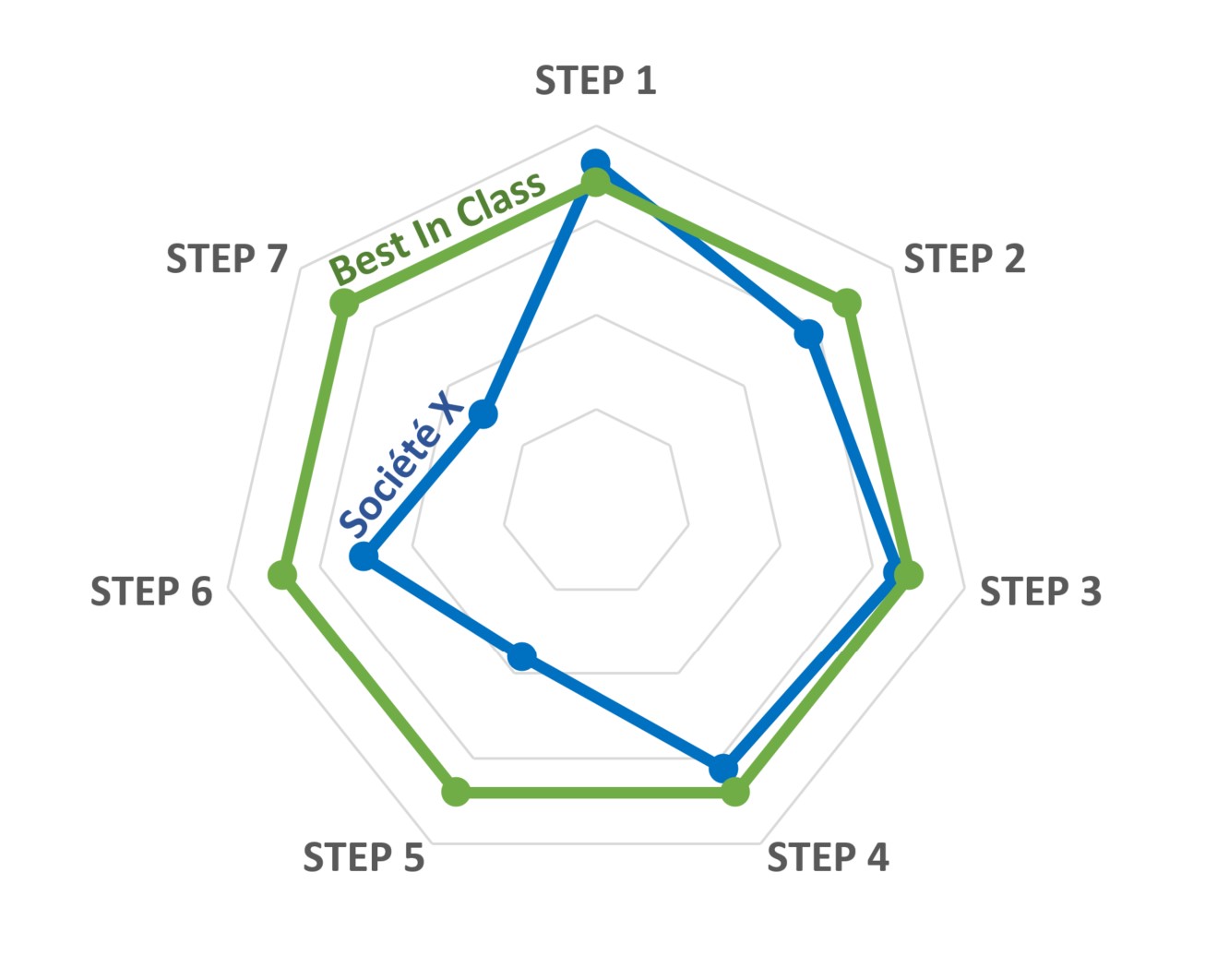

Several organizations have implemented LEAN tools (5S, Std Work, Kaizen, Andon, Kanban, Heijunka, SMED, TPM...), but do not achieve targeted results.

OUR DIAGNOSTIC

- Poor alignment with the organization strategy

- Lack of engagement from leaders

- Poor understanding of the required sequence of actions

- Lack of support at the operational level

- No integration into a management system

- Lack of engagement from leaders

- Poor understanding of the required sequence of actions

- Lack of support at the operational level

- No integration into a management system

OUR ADDED VALUE

- Several successful LEAN transformations led in Europe and internationaly

- Cooperation with experts involved at the start of LEAN at Toyota

- Specific approach fully adapted to your organization

- Specific approach fully adapted to your organization

OUR ENGAGEMENT

- Significant improvement in global performance (20%+)

Teams engagement, Safety, Quality, Velocity, Profitability

- Increased competences in your organization

- Sustainable performance improvements

- Sustainable performance improvements